Have you ever wondered how freeze drying works? Well, you’re in luck! In this article, we will explore the fascinating process of freeze drying and break it down into simple and easy-to-understand steps. From the initial freezing to the removal of moisture, we will take you on a journey through the world of freeze drying. So grab a cup of tea, sit back, and prepare to be amazed by the science behind this innovative technique. Let’s begin our exploration of how freeze drying works!

Understanding Freeze Drying

What is freeze drying?

Freeze drying, also known as lyophilization, is a preservation technique used to remove moisture from various products while preserving their original structure and composition. It involves freezing the product, removing the frozen water through sublimation, and then sealing the dried product in a moisture-proof container. This process allows for long-term storage of items without the need for refrigeration, while retaining their flavor, color, and nutritional value.

The process of freeze drying

The freeze drying process consists of several distinct steps, each contributing to the overall success of the preservation process. These steps include freezing, pre-treatment, primary drying, secondary drying, and final packaging. Let’s explore each step in detail to better understand how freeze drying works.

Benefits of freeze drying

Freeze drying offers numerous benefits that make it an ideal preservation method for a variety of products. Some of the key advantages include:

- Preservation of flavor, color, and nutrients: Freeze drying retains the original taste, color, and nutritional content of the products, resulting in high-quality preserved items.

- Long shelf life: The removal of moisture during freeze drying significantly extends the shelf life of the products, allowing them to be stored for an extended period without spoilage.

- Reduced weight and volume: Freeze drying removes water from the products, reducing their weight and volume significantly. This makes transportation and storage more convenient and cost-effective.

- Easy rehydration: When needed, freeze-dried products can be easily rehydrated by adding water, restoring them to their original form and texture.

- Extended storage without refrigeration: Unlike other preservation methods, freeze-dried products do not require refrigeration for storage, making them suitable for situations where refrigeration is not readily available.

Freeze Drying Process

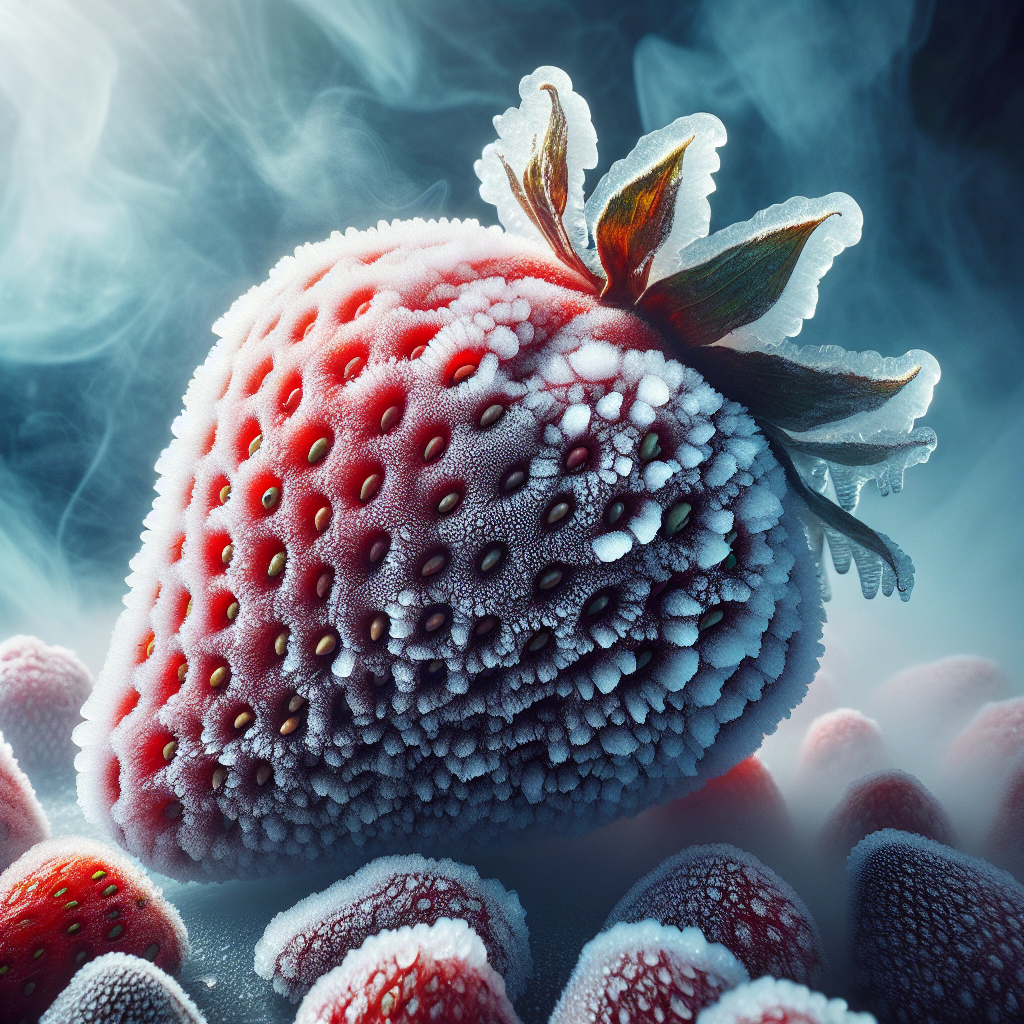

Step 1: Freezing

The first step in the freeze drying process is freezing. Freezing helps convert the water in the product from a liquid state into a solid state, preparing it for the subsequent drying process. The purpose of freezing is to immobilize the water molecules and facilitate their removal through sublimation during primary drying.

Different freezing methods can be used, depending on the nature of the product and the desired outcome. Some common freezing methods include direct contact freezing, indirect contact freezing, and immersion freezing. Each method has its own advantages and is selected based on factors such as product sensitivity, uniformity, and efficiency.

It is crucial to control both the temperature and the duration of freezing to achieve optimal results. The temperature should be low enough to freeze the product completely but not so low as to cause damage. The duration of freezing may vary depending on the product, and it is important to ensure that the entire product is frozen uniformly.

Step 2: Pre-treatment

Pre-treatment is an essential step in the freeze drying process, and it involves preparing the product for drying. The purpose of pre-treatment is to optimize the drying process and maintain the quality of the final product.

Common pre-treatment processes include washing, slicing, blanching, and applying additives such as antioxidants or stabilizers. These processes help remove unwanted substances, improve the product’s structural integrity, and prevent oxidation and enzymatic reactions that can affect the quality of the dried product.

By pre-treating the product before drying, it becomes easier to control the drying parameters and achieve the desired quality and characteristics in the final freeze-dried product.

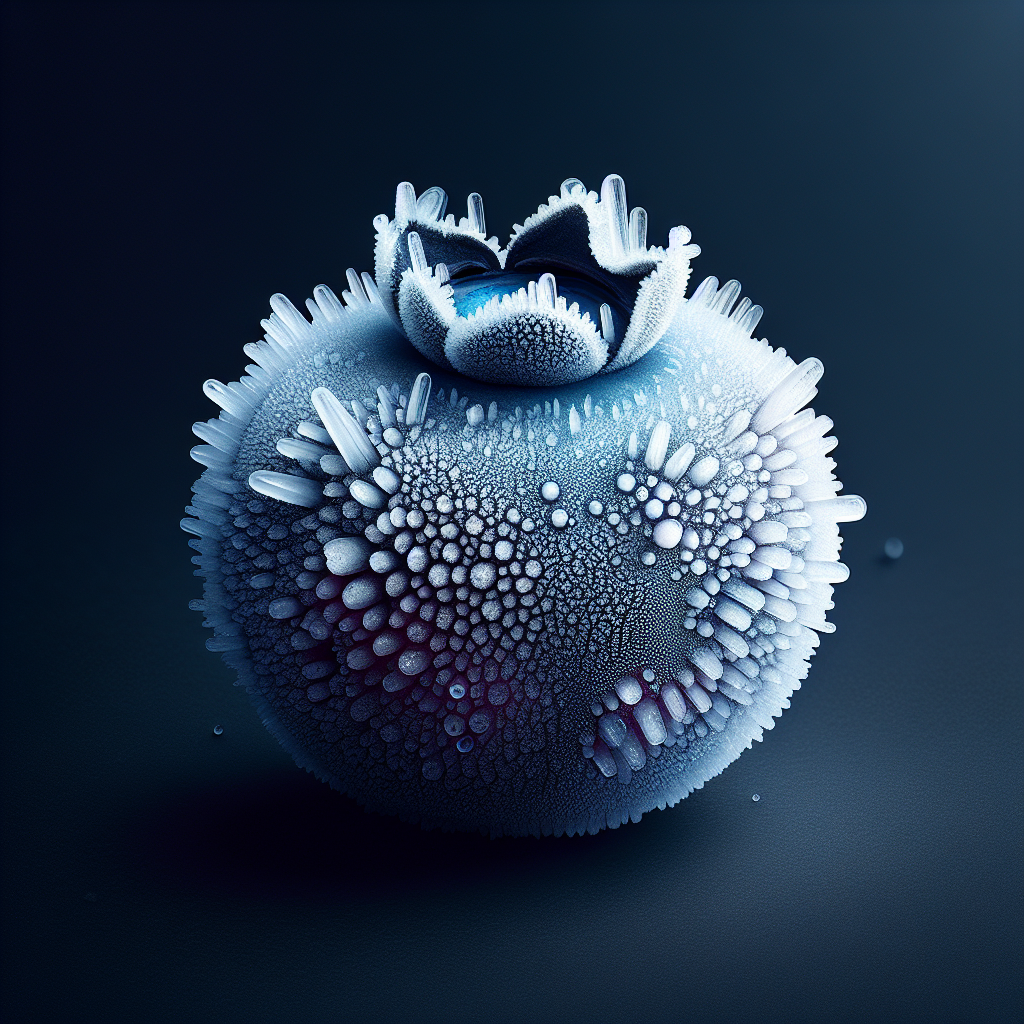

Step 3: Primary Drying

Primary drying is the most crucial step in the freeze drying process. It involves the removal of water from the frozen product by sublimation. Sublimation is the process by which water transitions directly from a solid state (ice) to a gaseous state (vapor) without passing through the liquid phase.

During primary drying, the moisture in the product is subjected to a vacuum, which lowers the pressure and allows the ice to sublimate. This process requires careful control of temperature and pressure to prevent excessive drying or prolonged drying times, both of which can impact the quality of the final product.

The primary drying phase can be time-consuming, as it relies on the slow and controlled sublimation of ice. However, the result is a product with a preserved structure and composition, ready for the next phase of drying.

Step 4: Secondary Drying

After the majority of the moisture has been removed during primary drying, the product enters the secondary drying phase. This step aims to remove any residual water that may be remaining in the product, ensuring its stability and long shelf life.

The secondary drying process involves the use of slightly higher temperatures than during primary drying to further promote water removal. Desorption, the process by which water molecules are liberated from the product matrix, occurs during this phase.

Controlling both temperature and pressure is critical during secondary drying to prevent overheating and achieve the desired level of moisture removal. The duration of secondary drying may vary depending on the product, but it is generally shorter than primary drying.

Step 5: Final Packaging

The final step in the freeze drying process is packaging the dried product. Proper packaging is essential to protect the product from moisture and external contaminants, ensuring its long shelf life and preserving its quality.

A suitable packaging material, such as moisture-proof and airtight containers, is selected to create a barrier between the product and the environment. This prevents the reabsorption of moisture and keeps the product’s structure intact.

Protecting freeze-dried products from moisture is crucial, as any exposure to humidity can lead to the rehydration of the product and spoilage. Additionally, proper packaging helps maintain the integrity of the freeze-dried products during transportation and storage, ensuring their availability for an extended period.

Benefits of Freeze Drying

Preservation of flavor, color, and nutrients

Freeze drying offers exceptional preservation of the flavor, color, and nutrients of the original products. Unlike other traditional drying methods, freeze drying ensures that the product retains its original qualities without compromising its taste or nutritional value. This makes freeze-dried products highly desirable for applications where quality is of utmost importance.

Long shelf life

One of the significant advantages of freeze drying is its ability to extend the shelf life of products. By removing moisture from the product, freeze drying prevents the growth of bacteria, molds, and other microorganisms that can cause spoilage. This allows for prolonged storage without the need for refrigeration, making freeze-dried products suitable for both domestic and commercial use.

Reduced weight and volume

Freeze drying significantly reduces the weight and volume of products without compromising their quality. The removal of water during the drying process results in a lightweight and compact product that is easy to transport and store. This reduction in weight and volume also contributes to cost savings in terms of packaging and shipping.

Easy rehydration

One of the notable benefits of freeze-dried products is their ease of rehydration. When water is added, the freeze-dried product quickly regains its original form, texture, and taste. This convenience makes freeze-dried products ideal for situations where quick and easy preparation is desired, such as camping, hiking, or emergency food supplies.

Extended storage without refrigeration

Unlike fresh or traditionally preserved products, freeze-dried items do not require refrigeration for storage. The removal of moisture ensures that the products remain stable and safe for consumption even at room temperature. This makes freeze-dried products a great option for situations where refrigeration is not readily available or feasible, such as during outdoor activities or in limited storage spaces.

Applications of Freeze Drying

Food and beverage industry

Freeze drying plays a vital role in the food and beverage industry. It is used to preserve a wide range of food items, including fruits, vegetables, meats, dairy products, and even complete meals. Freeze-dried foods are popular among outdoor enthusiasts, astronauts, and emergency preparedness kits due to their long shelf life, lightweight nature, and easy rehydration.

Pharmaceutical industry

The pharmaceutical industry extensively utilizes freeze drying to preserve medications, vaccines, and biological samples. Freeze-dried medications not only have an extended shelf life but also offer the advantage of improved stability and enhanced drug delivery. Vaccines, in particular, benefit from freeze drying as it allows for long-term storage and transportation without the need for refrigeration, making them more accessible in remote or underdeveloped areas.

Biotechnology and research

Freeze drying is widely adopted in biotechnology and research for the preservation of enzymes, proteins, antibodies, and other biological materials. The ability of freeze drying to retain the activity and integrity of these sensitive biomolecules makes it an essential tool in various fields, including diagnostics, medical research, and biopharmaceutical production.

Cosmetics and personal care

Freeze drying is also employed in the cosmetics and personal care industry. It is used to preserve natural ingredients, such as botanical extracts, essential oils, and skincare formulations. Freeze-dried cosmetic products have an extended shelf life, maintain their efficacy, and offer enhanced convenience in terms of handling and transportation.

Astronomy and space exploration

Lastly, freeze drying finds applications in astronomy and space exploration. Freeze-dried meals are commonly used by astronauts during space missions due to their reduced weight, long shelf life, and high nutrition content. Additionally, the removal of moisture through freeze drying helps preserve astronomical samples, such as meteorites, for scientific research and analysis.

Conclusion

Freeze drying is a versatile and effective preservation method that can be applied across various industries. By understanding the freeze drying process, its benefits, and its applications, we can appreciate its value and potential in preserving the quality, taste, and nutritional content of a wide range of products. Whether in the food industry, pharmaceuticals, research, cosmetics, or even in space exploration, freeze drying offers an innovative solution for long-term storage, convenience, and quality preservation. As technology advances, we can expect further advancements in freeze drying techniques and applications, opening up new possibilities for the future.