Ever wondered how to preserve your food for a longer period without losing its nutritional value? Look no further! In this comprehensive guide, we will take you through the fascinating world of freeze drying, specifically tailored for small-scale producers. Whether you’re a food enthusiast looking to extend the shelf life of your homemade goodies or a budding entrepreneur keen to explore the potential of freeze drying in your business, we’ve got you covered. With step-by-step instructions, helpful tables, and frequently asked questions, this article will equip you with all the knowledge you need to become a freeze-drying pro. So, let’s embark on this exciting journey together and unlock the secrets of freeze drying for small-scale production!

What is Freeze Drying?

Freeze drying, also known as lyophilization, is a process that involves removing water from a product to preserve it. This method is commonly used in food production, pharmaceuticals, and other industries to extend the shelf life of various products.

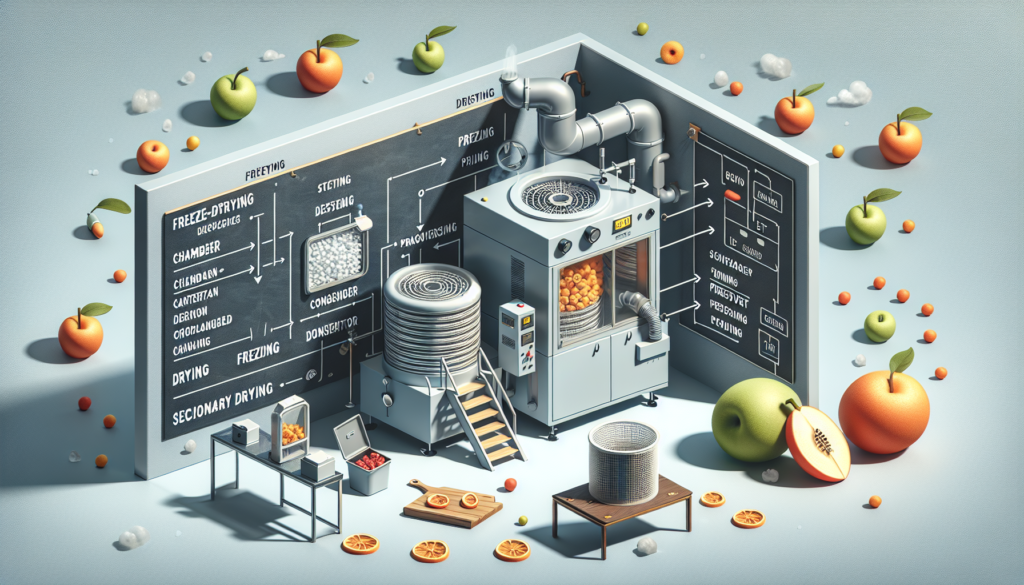

Understanding the Freeze Drying Process

The freeze drying process consists of several stages that work together to remove moisture from the product. It starts with freezing the product and then subjecting it to low pressure, which causes the frozen water to change from a solid to a gas without going through the liquid phase. This process is known as sublimation. By removing water through sublimation, the product’s structure and composition are preserved, and it can be stored for long periods without losing its quality.

Principles of Freeze Drying

Freeze drying relies on the principles of thermodynamics and sublimation. When the product is frozen, the water molecules within it turn into solid ice. Then, by applying low pressure and controlled heat, the frozen water crystals change directly from solid to vapor, bypassing the liquid phase. This vapor is then removed, leaving behind a freeze-dried product with minimal moisture content.

Benefits of Freeze Drying

Extended Shelf Life

One of the main benefits of freeze drying is the extended shelf life it provides. By removing the water from the product, the growth of bacteria, mold, and other microorganisms is inhibited, resulting in a longer shelf life compared to traditional drying methods.

Preservation of Nutritional Value

Freeze drying helps preserve the nutritional value of the product. The low temperatures used in the process minimize the loss of vitamins, minerals, and other sensitive nutrients that can be affected by heat.

Retains Color, Flavor, and Texture

Unlike traditional drying methods, freeze drying retains the color, flavor, and texture of the product. This is because the low temperatures and absence of liquid water during the drying process help prevent the degradation of these sensory attributes.

Reduced Weight and Increased Convenience

Freeze drying removes the water content from the product, resulting in a significant reduction in weight. This makes freeze-dried products lightweight, compact, and easy to transport and store. They also have a longer shelf life without the need for refrigeration, increasing convenience for both producers and consumers.

Choosing the Right Freeze Dryer

Consideration Factors

When choosing a freeze dryer, there are several factors to consider to ensure it meets your specific needs and requirements. Some important factors to consider include the type of product you want to freeze dry, the batch size you need to accommodate, your budget and cost constraints, and the available space in your production facility.

Type of Product

Different freeze dryers are designed for specific types of products. Consider the characteristics and requirements of your product, such as its size, shape, and moisture content. Some freeze dryers are better suited for liquid products, while others are more suitable for solid or powdered products.

Batch Size

The batch size you require will determine the capacity of the freeze dryer you need. Consider the volume of product you need to process in each batch, as well as the frequency of batches. It’s important to choose a freeze dryer that can handle your production volume efficiently.

Budget and Cost

Budget constraints are an important consideration when choosing a freeze dryer. Evaluate your available funds and determine how much you can invest in a freeze dryer without compromising the quality and efficiency of your freeze-drying process.

Available Space

The amount of available space in your production facility will also impact your choice of freeze dryer. Consider the dimensions and footprint of the freeze dryer you are considering and ensure it can be accommodated within your existing space constraints.

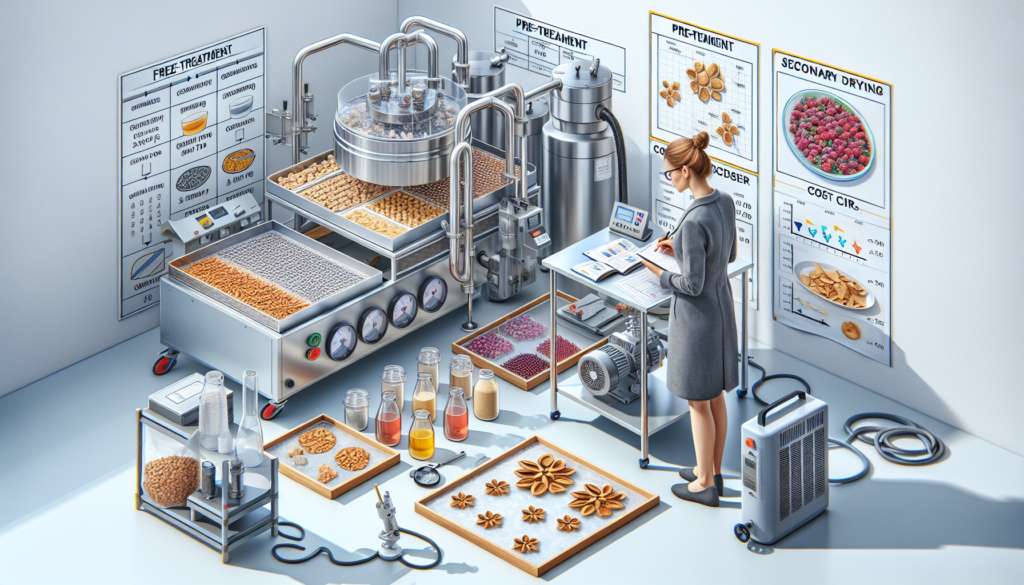

Preparing for Freeze Drying

Quality Assurance

Before freeze drying, ensure that your production processes and equipment are properly maintained to meet the highest standards of quality. Implement quality control measures, such as regular testing and monitoring, to ensure the safety and integrity of the products you are freeze drying.

Selecting Suitable Products

Not all products are suitable for freeze drying. Consider the characteristics and properties of your product, such as its moisture content, structure, and stability. Ideally, choose products that have low water activity and are not prone to degradation during the freeze-drying process.

Washing and Pre-Treating

Properly wash and pre-treat your products before freeze drying. This helps remove any contaminants or unwanted substances that may affect the quality and safety of the final freeze-dried product. Follow appropriate cleaning and pre-treatment procedures specific to your product.

Cutting or Slicing

If necessary, cut or slice your products into smaller pieces before freeze drying. This can help improve the freeze-drying process by reducing drying time and promoting uniform drying throughout the product.

Blanching or Steaming

Blanching or steaming certain products before freeze drying can help preserve their color, flavor, and texture. Blanching involves briefly boiling or steaming the product, followed by immediate cooling. This process helps deactivate enzymes that can cause browning and loss of texture.

Freezing the Product

After preparing the products, they need to be frozen before they can be freeze-dried. The freezing process converts the water content into solid ice, allowing for efficient removal during the freeze-drying process. Use appropriate freezing methods and temperatures suitable for your specific product.

Packaging and Labeling

Once the product is freeze-dried, it should be properly packaged and labeled. Choose suitable packaging materials that provide adequate protection against moisture, light, and oxygen. Label the packaging with all the necessary information, including product name, date of freeze drying, and any relevant instructions or warnings.

Freeze Drying Process

Loading the Freeze Dryer

Carefully load the frozen product into the freeze dryer, ensuring that it is evenly distributed and not overloaded. Proper loading promotes efficient and uniform freeze drying.

Pre-Freezing

Before starting the freeze-drying process, the product needs to be pre-frozen. This involves subjecting it to low temperatures to freeze the water content. Follow the recommended pre-freezing instructions specific to your freeze dryer model.

Primary Drying

Primary drying is the initial stage of the freeze drying process. It involves raising the temperature of the freeze dryer while maintaining low pressure. This causes the frozen water in the product to transition directly from a solid to a gas, without turning into liquid. This sublimation process helps remove the majority of the water content from the product.

Secondary Drying

After primary drying, secondary drying is carried out to remove any residual moisture from the product. This involves gradually increasing the temperature and further reducing the pressure to facilitate the sublimation of any remaining ice crystals. Secondary drying helps ensure the product is completely dry and free from moisture.

Post-Drying Operations

Once the freeze drying process is complete, it’s important to properly handle and store the freeze-dried product. Remove the product from the freeze dryer and package it in suitable containers. Store the freeze-dried product in a cool, dry place away from moisture, light, and heat.

Factors Affecting Freeze Drying

Temperature

Temperature is a crucial factor in freeze drying. Different products require specific temperature conditions during the freeze drying process to ensure optimal results. Carefully control and monitor the temperature throughout the process to avoid any negative effects on the product.

Pressure

The pressure within the freeze dryer affects the rate of sublimation and the efficiency of the freeze-drying process. The optimal pressure settings may vary depending on the product being freeze-dried. Adjust and maintain the pressure within the recommended range for your specific product.

Drying Time

The drying time required for freeze drying can vary depending on the product, its moisture content, and other factors. Ensure that you allow sufficient time for each drying phase to achieve the desired moisture removal and product quality.

Product Thickness

The thickness of the product being freeze-dried can impact the drying time and uniformity of drying. Thicker products may require longer drying times and careful monitoring to ensure complete drying throughout.

Product Composition

The composition of the product, including its fat content, sugar content, and other ingredients, can affect the freeze-drying process. Some products may require adjustments in temperature, pressure, or drying time to accommodate the specific composition.

Maintenance and Troubleshooting

Regular Cleaning

Regular cleaning of the freeze dryer is essential to maintain its efficiency and prevent any contamination. Follow the manufacturer’s recommendations for cleaning and sanitizing procedures. Pay particular attention to vacuum lines, shelves, and any other components that come into direct contact with the product.

Checking Vacuum Levels

Proper vacuum levels are crucial for effective freeze drying. Regularly check and monitor the vacuum levels during the drying process to ensure they are within the recommended range. Any deviations should be addressed promptly to prevent any adverse effects on the product.

Inspecting Heater Units

Heater units play a critical role in the freeze-drying process. Regularly inspect and maintain the heater units to ensure they are functioning optimally. Any malfunction or damage should be addressed promptly to avoid compromising the freeze-drying process.

Troubleshooting Common Issues

Despite preventive measures, freeze-drying issues may arise. Common problems include inadequate drying, improper product quality, or equipment malfunctions. Establish a troubleshooting plan to address these issues systematically and efficiently. Consult the freeze dryer manual or contact technical support for guidance when necessary.

Contacting Technical Support

If you encounter persistent issues or complex challenges with your freeze dryer, do not hesitate to contact technical support. They can provide expert guidance, troubleshooting assistance, and maintenance recommendations to ensure optimal performance and product quality.

Packaging and Storage

Choosing Suitable Packaging

Select packaging materials that provide adequate protection for your freeze dried products. Consider factors such as moisture barrier properties, light protection, and oxygen permeability. Choose packaging options that are compatible with your product and maintain its quality during storage.

Proper Sealing Techniques

Proper sealing of the packaging is essential to maintain the quality and integrity of the freeze-dried product. Use appropriate sealing techniques, such as heat sealing or vacuum sealing, to ensure an airtight seal. Follow the packaging manufacturer’s instructions for the best results.

Storage Conditions

To maximize the shelf life of your freeze-dried products, store them in appropriate conditions. Keep the products in a cool, dry place away from direct sunlight, moisture, and temperature fluctuations. Ensure that the storage area is clean and free from any contaminants that could compromise the product’s quality.

Monitoring Shelf Life

Monitor the shelf life of your freeze-dried products to ensure their freshness and quality. Establish a system for tracking production dates, batch numbers, and expiration dates. Periodically sample and evaluate the products to confirm their stability and nutritional content over time.

Cost Considerations

Electricity Consumption

The freeze drying process requires energy to power the equipment, particularly the vacuum pumps and refrigeration systems. Consider the electricity consumption of the freeze dryer when evaluating the cost of freeze drying operations. Energy-efficient freeze dryers can help reduce long-term operating costs.

Cost of Freeze Dryer

The initial investment in a freeze dryer can vary depending on factors such as size, capacity, and features. Consider the cost of the freeze dryer and the potential return on investment over time. Evaluate the quality, performance, and reliability of the equipment to ensure it meets your needs effectively.

Packaging and Storage Costs

In addition to the cost of the freeze dryer, consider the costs associated with packaging and storage. These costs can vary depending on the materials used, the volume of products being packaged, and the storage requirements. Carefully assess these expenses to ensure they are accounted for in your freeze drying budget.

Return on Investment

When considering the cost of freeze drying, it’s important to evaluate the potential return on investment. Assess the market demand for freeze-dried products and the potential profitability of your offerings. Consider factors such as product pricing, sales volume projections, and market competition to determine the viability of your freeze drying operations.

Marketing and Selling Freeze Dried Products

Understanding the Target Market

To successfully market and sell freeze-dried products, it’s important to understand the target market. Research consumer preferences, trends, and demands related to freeze-dried products. Consider factors such as target demographics, lifestyles, and dietary preferences to tailor your marketing strategies effectively.

Packaging and Branding

Packaging and branding play a crucial role in attracting consumers and differentiating your freeze-dried products from competitors. Develop visually appealing, informative, and functional packaging that highlights the product’s benefits and features. Create a brand identity that aligns with your target market and effectively communicates the value of your freeze-dried products.

Distribution Channels

Identify the most suitable distribution channels for your freeze-dried products. Consider options such as online sales platforms, specialty stores, supermarkets, and direct-to-consumer channels. Evaluate the costs, reach, and target audience of each distribution channel to optimize your sales and reach a wider customer base.

Promotion Strategies

Promote your freeze-dried products through targeted marketing campaigns. Utilize various marketing channels, such as social media, online advertising, traditional advertising, and content marketing. Highlight the unique qualities of your freeze-dried products, such as their extended shelf life, nutritional value, and convenience. Develop engaging and informative content that educates consumers about the benefits and uses of freeze-dried products.

By understanding the freeze drying process, choosing the right freeze dryer, preparing the products correctly, and following proper maintenance and storage practices, small-scale producers can successfully incorporate freeze drying into their operations. With its numerous benefits and potential for extended shelf life, freeze drying offers an effective method for preserving and marketing a wide range of products in various industries.