Are you tired of missing out on your favorite fruits and vegetables when they aren’t in season? Well, fret no more! Freeze drying is here to save the day. This innovative technique preserves the flavors and nutrients of your favorite seasonal produce, allowing you to enjoy them all year round. In this article, we will dive into the world of freeze drying, exploring how it works and why it is the perfect solution for your fruit and vegetable needs. So, grab a snack and get ready to learn all about this incredible process!

Benefits of Freeze Drying

Freeze drying is an excellent method for preserving fruits and vegetables, as it offers numerous benefits that make it a preferred choice for many. Let’s take a closer look at some of the key advantages of freeze drying:

Retains Nutritional Value

One of the most significant benefits of freeze drying is that it retains the nutritional value of the fruits and vegetables. Unlike other preservation methods like canning or drying, freeze drying doesn’t involve high heat, which can degrade the vitamins, minerals, and enzymes present in the produce. As a result, freeze-dried fruits and vegetables maintain their original nutritional composition, providing you with a healthy and wholesome snack or ingredient.

Long Shelf Life

Another advantage of freeze-dried fruits and vegetables is their extended shelf life. Through the freeze drying process, water is removed from the produce, preventing the growth of bacteria, mold, and yeast that can cause spoilage. The low moisture content in freeze-dried foods ensures a longer shelf life, allowing you to enjoy your favorite seasonal fruits and vegetables throughout the year without worrying about them going bad. This shelf stability is particularly beneficial for those who love to stock up on ingredients or prepper enthusiasts.

Convenient and Easy to Store

Freeze-dried fruits and vegetables are incredibly convenient and easy to store. Once freeze drying is complete, the food is packaged in lightweight and compact containers, making it easy to store in your pantry, backpack, or emergency kit. The reduced weight and volume of freeze-dried foods make them ideal for camping trips, hiking, or any outdoor adventure where space and weight are a concern. Additionally, freeze-dried foods are quick and easy to rehydrate, allowing you to enjoy the flavors and textures of fresh produce with minimal effort.

Freeze Drying Process

To understand why freeze drying is such an effective preservation method, it’s essential to grasp the process involved. Freeze drying typically consists of three main stages: pre-freezing, primary drying, and secondary drying.

Pre-Freezing

The first step in the freeze drying process is pre-freezing the fruits or vegetables. This involves freezing the produce at extremely low temperatures, usually around -40 degrees Fahrenheit (-40 degrees Celsius), to solidify the water content within the food. Pre-freezing helps to preserve the structure and cellular integrity of the produce, allowing it to retain its shape, color, and texture during the subsequent drying stages.

Primary Drying

After pre-freezing, the frozen produce is transferred into a vacuum chamber. In this chamber, the pressure is reduced while heat is applied, enabling the ice within the food to sublime directly from a solid to a gas without passing through a liquid state. This process is called sublimation, and it removes the majority of the moisture from the food, leaving it in a freeze-dried state.

Secondary Drying

The last stage of the freeze drying process is secondary drying. In this phase, any residual moisture that may remain in the food is eliminated to ensure maximum preservation and prevent spoilage. The temperature in the vacuum chamber is gradually increased, causing any remaining ice particles to sublime, removing the last traces of moisture from the freeze-dried food. Secondary drying helps to enhance the shelf stability and quality of the end product, making it safe for long-term storage.

Preparation of Fruits and Vegetables for Freeze Drying

Before undergoing the freeze drying process, it’s important to properly prepare the fruits and vegetables. Here are the key steps involved in the preparation process:

Selection of High-Quality Produce

To ensure the best results, it’s crucial to choose high-quality, ripe fruits and vegetables for freeze drying. Select produce that is at its peak freshness, as this will help retain the best flavor, texture, and nutritional content during the freeze drying process. Avoid using produce that is overripe, bruised, or showing signs of spoilage, as this can negatively affect the final freeze-dried product.

Sorting and Washing

After selecting the produce, thoroughly sort and wash the fruits and vegetables. Remove any damaged or spoiled parts, and trim them to uniform sizes. Washing ensures that the produce is free from dirt, pesticides, and any other contaminants that may be present.

Blanching

Blanching is a crucial step in preparing fruits and vegetables for freeze drying. This involves briefly immersing the produce in boiling water or steam, followed by quick cooling in ice water. Blanching helps to inactivate enzymes that can cause discoloration, flavor loss, and texture changes during storage. It also helps to preserve the nutritional content and overall quality of the freeze-dried food.

Freeze Drying Equipment and Supplies

To successfully freeze dry fruits and vegetables at home, you will need the appropriate equipment and supplies. Here are the essential components for the freeze drying process:

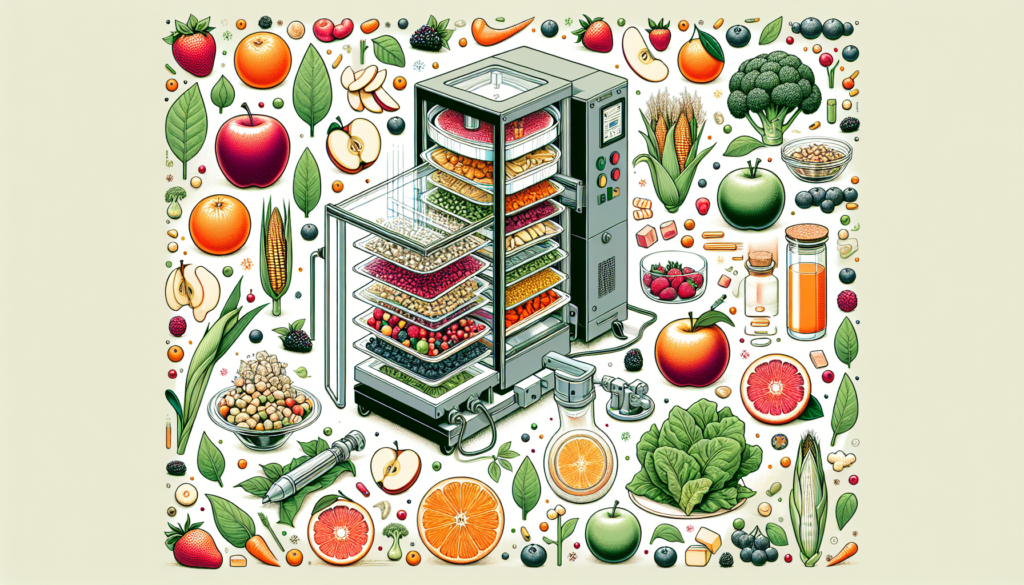

Freeze Drying Machine

A freeze drying machine, also known as a freeze dryer, is the core equipment needed for freeze drying. It consists of a vacuum chamber, shelves or trays, and temperature control mechanisms. Freeze drying machines are available in different sizes and capacities, allowing you to choose one that suits your needs and available space.

Vacuum Chamber

The vacuum chamber is an integral part of the freeze drying machine. It creates a low-pressure environment necessary for the sublimation of ice within the food. The vacuum chamber ensures that the freeze-dried food remains at a consistent pressure throughout the drying process, resulting in high-quality, shelf-stable products.

Trays and Containers

Trays and containers are used to hold the fruits and vegetables during the freeze drying process. They should be made of food-grade materials that are resistant to extreme temperatures. The trays and containers should be spacious enough to accommodate the produce without overcrowding, allowing sufficient airflow for efficient freeze drying.

Steps to Freeze Dry Fruits and Vegetables

Now that you understand the benefits of freeze drying and have the necessary equipment and supplies, let’s take a closer look at the step-by-step process of freeze drying fruits and vegetables:

Preparation

Start by selecting high-quality produce and preparing them by sorting, washing, and blanching as mentioned earlier. Ensure that the fruits and vegetables are properly cleaned and cut into uniform slices or pieces.

Pre-Freezing

Once the produce is prepared, arrange the slices or pieces on trays or containers and place them in the freezer. Pre-freeze the produce at a temperature of around -40 degrees Fahrenheit (-40 degrees Celsius) until it is completely frozen. Pre-freezing prepares the produce for the subsequent drying stages.

Loading the Freeze Dryer

After pre-freezing, load the frozen produce into the trays or containers and arrange them in the freeze dryer. Ensure that the trays or containers are evenly spaced and not overcrowded, allowing sufficient airflow during the freeze drying process.

Primary Drying

Once the produce is loaded into the freeze dryer, begin the primary drying phase. Start the freeze drying machine, setting the appropriate time and temperature according to the specific requirements of the produce you are freeze drying. During primary drying, the frozen water within the produce sublimes, evaporating from a solid to a gas and being removed from the food.

Secondary Drying

After completing the primary drying phase, proceed to the secondary drying stage. Gradually increase the temperature in the freeze dryer to allow any residual moisture to evaporate completely. This step ensures that the freeze-dried fruits and vegetables have minimal moisture content, preventing microbial growth and spoilage during storage.

Sealing and Storage

Once the freeze drying process is complete, remove the trays or containers from the freeze dryer. Seal the freeze-dried fruits and vegetables in airtight packaging to maintain their freshness and integrity. Store the sealed packages in a cool, dry place away from direct sunlight, heat, and moisture to ensure maximum shelf life.

Tips for Successful Freeze Drying

To achieve the best results with freeze drying, consider the following tips:

Choose Ripe and Fresh Produce

Select fruits and vegetables that are ripe and fresh for freeze drying. Ripe produce contains higher levels of natural sugars, resulting in a better flavor profile in the freeze-dried product.

Slice Uniformly

When preparing the produce for freeze drying, ensure that the slices or pieces are uniform in size. This allows for even drying and ensures consistent results.

Blanching Time and Temperature

Pay attention to the blanching time and temperature for different types of produce. Proper blanching helps preserve the flavor, color, and texture of the freeze-dried food.

Proper Loading of Freeze Dryer

When loading the freeze dryer, avoid overcrowding the trays or containers. Ensure proper spacing between the slices or pieces to allow sufficient airflow throughout the drying process.

Storing Freeze Dried Fruits and Vegetables

Proper storage is essential to maintain the quality and longevity of freeze-dried fruits and vegetables. Here are some guidelines to follow:

Packaging and Sealing

Transfer the freeze-dried fruits and vegetables into airtight packaging, such as vacuum-sealed bags or containers. Press out as much air as possible before sealing to prevent moisture and air from entering the package.

Optimal Storage Conditions

Store the sealed packages of freeze-dried foods in a cool, dry place with a constant temperature. Avoid exposure to sunlight, heat, and humidity, as these can degrade the quality and nutritional value of the freeze-dried products.

Shelf Life

When stored under proper conditions, freeze-dried fruits and vegetables can have an impressive shelf life. Generally, they can remain safe to consume for up to 25 years, although the optimal quality may vary depending on the specific produce and storage conditions.

Rehydrating Freeze Dried Foods

Rehydrating freeze-dried fruits and vegetables is simple and allows you to enjoy their flavors and textures as if they were fresh. Here are some tips for rehydration:

Water-To-Food Ratio

The water-to-food ratio may vary depending on the specific produce, but as a general guideline, use about one cup of water to one cup of freeze-dried food. Adjust the amount of water as needed to achieve the desired consistency.

Rehydration Methods

There are several methods for rehydrating freeze-dried foods. The most common method is to add the freeze-dried food to a bowl of water and let it soak for a few minutes until it becomes plump and rehydrated. Alternatively, you can add the freeze-dried food directly to soups, stews, or other liquid-based dishes during cooking.

Using Freeze Dried Foods in Recipes

Freeze-dried fruits and vegetables can be used in various recipes to add flavor, texture, and nutrition. They can be sprinkled on top of cereals, yogurt, or salads, blended into smoothies, incorporated into baked goods, or rehydrated and used as ingredients in savory dishes.

Cost Considerations

While freeze drying offers numerous benefits, it’s important to consider the cost implications before diving into the process. Here are some factors to keep in mind:

Initial Investment in Equipment

Freeze drying machines can be quite expensive, and the initial investment can be a significant consideration. Consider the cost, size, capacity, and maintenance requirements of the freeze dryer before making a purchase decision.

Energy Consumption

Freeze drying can be energy-intensive, especially during the primary and secondary drying stages. Be mindful of the energy consumption of the freeze drying machine and factor it into your overall cost considerations.

Versus Other Preservation Methods

Compare the cost of freeze drying to other preservation methods like canning, freezing, or dehydrating. Take into account the time, effort, and resources required for each method before deciding which one is most suitable for your needs.

FAQs about Freeze Drying

Here are some frequently asked questions about freeze drying:

What is freeze drying?

Freeze drying is a preservation method that involves removing water from food by freezing it and then subjecting it to a vacuum environment, causing the ice to sublime and transform directly into a gas. This process preserves the structure, flavor, nutritional content, and shelf life of the food.

Is freeze drying the same as dehydration?

No, freeze drying is not the same as dehydration. While both methods reduce the moisture content of food, freeze drying involves freezing the food and removing the water via sublimation, while dehydration typically involves applying heat to remove the moisture.

Can I freeze dry vegetables at home?

Yes, it is possible to freeze dry vegetables at home using a freeze drying machine. However, it’s important to ensure that you have the necessary equipment, proper food handling practices, and an understanding of the freeze drying process to achieve safe and high-quality results.