In the world of pharmaceuticals, freeze drying has become a widely used technique with numerous applications. From preserving delicate vaccines to extending the shelf life of antibiotics, freeze drying has proven to be an invaluable process. This article will take you on a journey through the fascinating world of freeze drying in the pharmaceutical industry, providing insights into its applications, benefits, and how it works. So, get ready to explore the cold frontier of pharmaceutical preservation and discover how freeze drying is revolutionizing the way we store and distribute vital medications.

Overview

In the ever-evolving field of pharmaceuticals, freeze drying is a process that has gained significant recognition. Also known as lyophilization, freeze drying involves the removal of moisture from a product while preserving its integrity and quality. This article explores the various benefits of freeze drying, the process itself, and its applications in the pharmaceutical industry.

Benefits of Freeze Drying

Freeze drying offers several advantages that make it a popular choice in the pharmaceutical industry. Firstly, it allows for the long-term preservation of sensitive pharmaceutical products. By removing moisture, freeze drying eliminates the risk of microbial growth and chemical degradation, thus extending the shelf life of medications. Secondly, freeze-dried products retain their original properties, including potency, efficacy, and appearance, making them highly desirable for pharmaceutical manufacturers. Lastly, the lightweight and compact nature of freeze-dried products make them ideal for storage, transportation, and distribution, resulting in cost savings for both suppliers and consumers.

Process of Freeze Drying

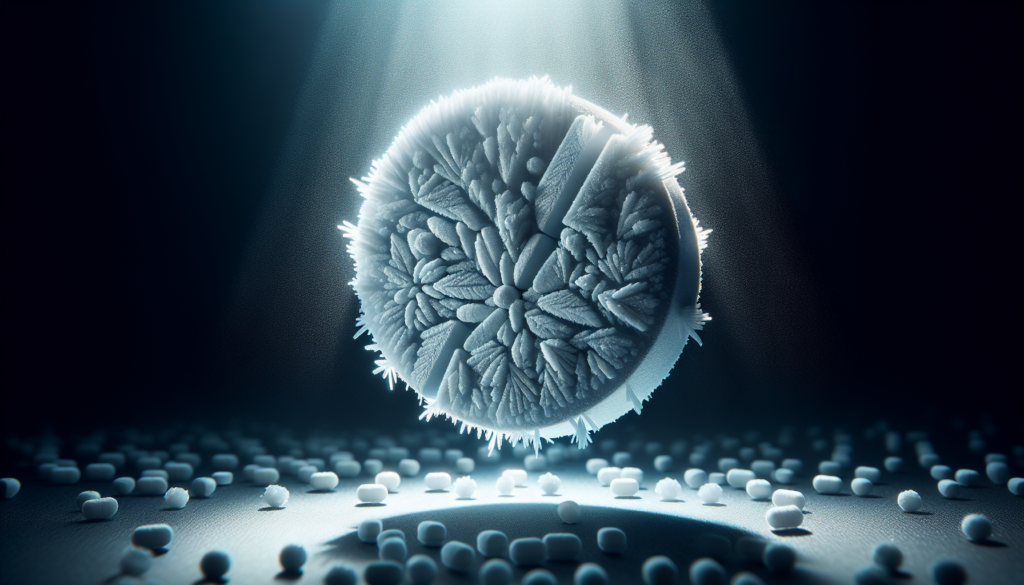

The freeze-drying process involves three main steps: freezing, primary drying, and secondary drying. During the freezing stage, the product is cooled to sub-zero temperatures, typically by placing it in a freezer or using specialized equipment. Freezing converts the product into a solid state, enabling it to retain its structure during the subsequent drying process.

After freezing, the primary drying phase begins. This step involves reducing the pressure in the environment surrounding the product, causing the ice to sublime directly from a solid to a gas state. To facilitate sublimation, the freeze-drying equipment applies heat to the product, allowing the ice to evaporate. This process removes the majority of the moisture from the product, leaving behind a freeze-dried solid.

The final stage, known as secondary drying, involves further removal of moisture by applying a higher temperature and vacuum. This step is crucial to ensure that the product reaches and maintains a low moisture content, preventing any microbial growth or degradation. Once the secondary drying is complete, the freeze-dried product is sealed in moisture-resistant packaging to maintain its stability until use.

Applications of Freeze Drying in the Pharmaceutical Industry

1. Preservation of Vaccines

One of the primary applications of freeze drying in the pharmaceutical industry is the preservation of vaccines. Vaccines are sensitive biological products that require careful handling and storage to maintain their efficacy. Freeze drying enables the removal of water without affecting the vaccine’s structure, allowing for long-term preservation. This process ensures that vaccines can be shipped and stored at lower temperatures, reducing the need for cold chain infrastructure and increasing accessibility, particularly in areas with limited resources.

2. Production of Drugs

Freeze drying plays a crucial role in the production of various pharmaceutical drugs. Many drugs are heat-sensitive and can undergo chemical degradation when exposed to high temperatures or moisture. By freeze drying these drugs, manufacturers are able to remove the water content while preserving their efficacy. Freeze-dried drugs also have a longer shelf life, reducing the need for frequent production and minimizing waste.

3. Formulation of Biologics

Biologics, including antibodies, proteins, and enzymes, are widely used in the pharmaceutical industry for therapeutic purposes. Freeze drying enables the formulation of biologics by preserving their stability and potency. As these complex molecules require careful handling to avoid denaturation, freeze drying offers a gentle and effective method to remove moisture. This process allows biologics to be stored at room temperature and reconstituted when needed, providing convenience and ease of use for patients and healthcare providers.

4. Creation of Parenteral Products

Parenteral products, such as injectables and infusions, require sterile delivery to ensure patient safety. Freeze drying is commonly employed in the creation of these products due to its ability to remove moisture without compromising the drug’s integrity. By freeze drying parenteral products, pharmaceutical companies can achieve longer shelf life, improved stability, and reduced risk of contamination. Additionally, freeze-dried parenteral products offer convenience in healthcare settings, as they can be easily reconstituted with a compatible diluent prior to use.

5. Manufacturing of Inhalation Products

Inhalation products, such as dry powder inhalers and nasal sprays, are popular pharmaceutical formulations for respiratory conditions. Freeze drying is an essential process in the manufacturing of these products as it allows for the removal of moisture without altering the particles’ aerodynamic properties. This ensures consistent and effective drug delivery to the respiratory system. Furthermore, freeze-dried inhalation products offer enhanced stability, prolonged shelf life, and improved patient convenience by eliminating the need for refrigeration.

6. Preparation of Lyophilized Products

Lastly, freeze drying is widely used in the preparation of various lyophilized products, which include diagnostic reagents, reconstituted medications, and laboratory media. By freeze drying these products, pharmaceutical manufacturers can eliminate the need for refrigeration and achieve long-term stability. Lyophilized products are easy to transport, have reduced risk of contamination, and can be reconstituted quickly when needed. This makes them highly desirable in both clinical and research settings, where convenience and reliability are paramount.

In conclusion, freeze drying plays a critical role in the pharmaceutical industry, offering numerous benefits and applications. From the preservation of vaccines to the formulation of biologics and the creation of parenteral and inhalation products, freeze drying enables the production of high-quality medications. By removing moisture while maintaining the product’s integrity, freeze drying ensures the stability, efficacy, and long-term preservation of pharmaceuticals, contributing to advancements in patient care and access to essential medications.