Are you curious about freeze drying and dehydrating? Well, you’re in luck because we’re here to shed some light on these two food preservation methods. Freeze drying and dehydrating are both popular techniques, but which one is better? That’s what we’re about to find out. In this article, we’ll explore the differences between freeze drying and dehydrating, their advantages and disadvantages, and give you some practical tips to help you decide which method suits your needs best. So, grab a cup of tea and let’s dive into the world of food preservation!

I. Overview

A. Definition of freeze drying

Freeze drying, also known as lyophilization, is a food preservation method that involves freezing the food and then removing the ice crystals through a process called sublimation. Sublimation is the conversion of water from solid ice directly into vapor without going through the liquid phase. This process helps to retain the structure, shape, and nutritional content of the food while removing the moisture.

B. Definition of dehydrating

Dehydrating, on the other hand, is a food preservation method that involves removing the water content from the food by using heat. This process helps to inhibit the growth of bacteria, yeast, and mold, as they require moisture to thrive. Dehydrating can be done through various methods such as air-drying, sun-drying, or using a food dehydrator.

C. Importance of food preservation

Food preservation is crucial for ensuring food safety, preventing food spoilage, and extending the shelf life of perishable food items. By preserving food, we can reduce food waste and have access to nutritious meals even during times of scarcity. Both freeze drying and dehydrating are effective methods of food preservation that help to maintain the nutritional value, taste, and texture of the food.

II. Process

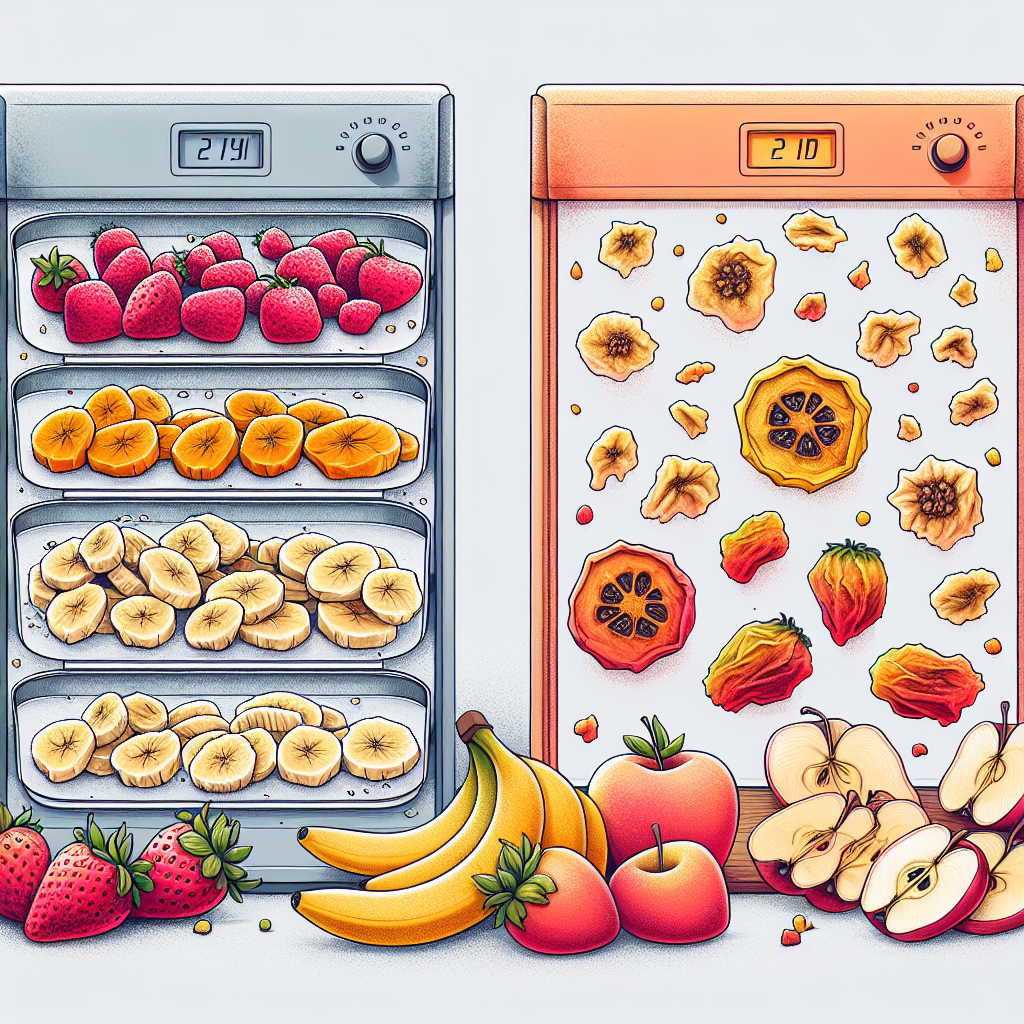

A. Freeze drying process

The freeze drying process involves several steps. First, the food is frozen rapidly at extremely low temperatures. During the freezing phase, ice crystals are formed within the food. The second step is primary drying, where the pressure is reduced, and heat is applied to cause sublimation. This removes the ice crystals, leaving behind a freeze-dried food product. The final step is secondary drying, where any remaining moisture is removed from the product. This process helps to preserve the food’s nutritional integrity while extending its shelf life.

B. Dehydrating process

Dehydrating is a simpler process compared to freeze drying. The food is sliced or chopped into thin pieces to increase the surface area. It is then exposed to heat, either through air-drying or using a food dehydrator. The heat removes the moisture from the food, preventing the growth of microorganisms and enzymatic activity. The outcome of the dehydrating process is a lightweight, shriveled food product that can be stored for a longer duration.

III. Equipment

A. Freeze drying equipment

Freeze drying requires specialized equipment such as a freeze dryer. A freeze dryer consists of a vacuum chamber, condenser, refrigeration system, and control panel. It works by freezing the food and then creating a vacuum environment to facilitate the sublimation process. While freeze drying equipment can be expensive, it is a worthwhile investment for those who frequently preserve large quantities of food.

B. Dehydrating equipment

Dehydrating equipment is more readily available and affordable compared to freeze drying equipment. It can take the form of a simple food dehydrator or even an oven set to a low temperature. Food dehydrators have trays that allow for even air circulation, ensuring uniform drying. These devices are user-friendly and require minimal maintenance, making them a popular choice for home food preservation.

C. Cost comparison

When it comes to cost, dehydrating is generally more budget-friendly compared to freeze drying. Freeze drying equipment can range from a few thousand dollars for small-scale units to tens of thousands of dollars for larger industrial-grade equipment. Dehydrating equipment, on the other hand, can be purchased for as low as $50, depending on the brand and features. It’s important to consider your needs, budget, and volume of food preservation before deciding on the equipment.

IV. Time Required

A. Freeze drying time

Freeze drying is a time-consuming process compared to dehydrating. The freeze drying time varies depending on factors such as the type of food, thickness of the slices, and the capacity of the freeze dryer. On average, freeze drying can take anywhere from 24 to 48 hours. However, it’s important to note that the actual drying time may be longer when considering the pre-freezing and post-drying steps.

B. Dehydrating time

Dehydrating is relatively faster compared to freeze drying. The time required for dehydrating depends on various factors such as the moisture content of the food, the ambient humidity, and the drying method used. Generally, it can take anywhere from a few hours to a day or two to dehydrate food completely. Thicker pieces of food may take longer to dry compared to thinner slices.

V. Nutritional Value

A. Freeze drying and nutrition

Freeze drying holds a significant advantage over dehydrating when it comes to retaining the nutritional value of food. The freeze drying process minimizes nutrient loss by preserving the original structure and cellular integrity of the food. It also helps to retain essential vitamins, minerals, and enzymes, making freeze-dried foods a nutritious option.

B. Dehydrating and nutrition

Dehydrating can cause some nutrient loss due to the exposure of food to heat. However, the extent of nutrient loss depends on the type of nutrient and the drying temperature used. Certain heat-sensitive vitamins and enzymes may be partially degraded during the dehydrating process. Despite this, dehydrated foods still retain a considerable amount of nutrients and can be a valuable addition to a balanced diet.

C. Comparing nutritional retention

In terms of nutritional retention, freeze drying generally outperforms dehydrating. The freeze drying process enables foods to retain a higher percentage of their original nutritional content compared to dehydrating. However, it’s important to note that both methods significantly prolong the shelf life of food while retaining a reasonable amount of nutrients compared to other preservation methods such as canning or freezing.

VI. Taste and Texture

A. Freeze drying and taste

Freeze-dried foods often retain their original taste and flavor thanks to the preservation of volatile compounds responsible for aroma and taste. The freeze drying process minimizes the alterations in taste, making freeze-dried foods a popular choice for gourmet meals, camping trips, and emergency food supplies. The removal of moisture also intensifies the flavors, resulting in a concentrated taste experience.

B. Dehydrating and taste

Dehydrated foods may undergo some flavor and taste changes due to the exposure to heat. However, many people still find the taste of dehydrated foods pleasant and enjoyable. Some foods, such as dried fruits or jerky, develop a natural sweetness or savory flavor during the dehydrating process. The taste of dehydrated food can be further enhanced by proper seasoning or the addition of spices before drying.

C. Texture comparison

Freeze-dried foods retain their original texture to a large extent, giving them a crispy and crunchy texture when rehydrated. On the other hand, dehydrated foods tend to become chewy and leathery due to the removal of moisture. However, texture preferences vary among individuals, and some may prefer the soft and chewy texture of dehydrated foods. It ultimately comes down to personal preference and the desired application.

VII. Shelf Life

A. Freeze drying and shelf life

Freeze-dried foods have an exceptionally long shelf life compared to dehydrated foods. When stored properly in airtight containers, freeze-dried foods can last anywhere from 20 to 30 years. The removal of moisture during the freeze drying process helps to inhibit the growth of bacteria, mold, and yeast, which are responsible for food spoilage. This extended shelf life makes freeze-dried foods an excellent option for long-term food storage and emergency preparedness.

B. Dehydrating and shelf life

Dehydrated foods also have a good shelf life, although not as long as freeze-dried foods. Depending on the food type and storage conditions, dehydrated foods can typically last anywhere from 1 to 5 years. Proper packaging, such as vacuum-sealed bags or airtight containers, can help to extend the shelf life. It’s crucial to store dehydrated foods in a cool, dry, and dark place to maintain their quality and safety.

C. Factors affecting shelf life

Several factors can affect the shelf life of both freeze-dried and dehydrated foods. Exposure to moisture, light, heat, and oxygen can accelerate the degradation process and lead to spoilage. It’s essential to store preserved foods in appropriate containers, away from direct sunlight and fluctuating temperatures. Regular inspections for signs of spoilage, such as unusual odors or discoloration, are necessary to ensure the safety of the stored food.

VIII. Storage and Space

A. Freeze drying and storage

Freeze-dried foods are lightweight and compact, making them convenient for storage and transportation. Due to the removal of moisture, freeze-dried foods take up significantly less space compared to their fresh counterparts. They can be easily stored in sealed bags, jars, or cans, which saves space in your pantry or emergency preparedness kit. The reduced weight also makes freeze-dried foods an excellent option for backpacking and camping trips.

B. Dehydrating and storage

Dehydrated foods are also lightweight and take up less space compared to fresh foods. However, they are relatively bulkier compared to freeze-dried foods due to the preservation of some moisture content. Dehydrated foods can be stored in airtight containers or vacuum-sealed bags to protect them from moisture and contaminants. It’s important to consider the available storage space and the quantity of preserved food when choosing between freeze-drying and dehydrating.

C. Space requirements

In terms of space requirements, freeze-dried foods have the advantage. If you have limited storage space or need to stock up on food for emergencies, freeze-dried foods offer a more efficient use of space. However, if you have ample storage space or prefer bulkier food items, dehydrating can be a viable option. Consider your storage capacity and existing shelf space when deciding which preservation method suits your needs.

IX. Cost

A. Freeze drying cost

The cost of freeze drying can be higher compared to dehydrating. In addition to the initial investment in freeze drying equipment, the process itself can be more energy-intensive. Freeze drying requires electricity to maintain low temperatures and facilitate sublimation. However, the cost of freeze drying can be offset by the longer shelf life, superior nutritional retention, and convenience it offers.

B. Dehydrating cost

Dehydrating is generally more cost-effective compared to freeze drying. The equipment required for dehydrating is more affordable, and the process consumes significantly less energy. Dehydrating can be done using a food dehydrator or an oven set to a low temperature, which are common household appliances. Overall, dehydrating is a more budget-friendly option for those who want to preserve food without substantial financial investment.

C. Cost savings

Both freeze drying and dehydrating can result in cost savings in the long run. By preserving food, you can take advantage of bulk purchases, seasonal produce, or homegrown harvests. Preserving food also helps to reduce food waste, allowing you to save money by eliminating the need to throw away spoiled food. Additionally, having a stockpile of preserved food can be a cost-effective strategy for emergency preparedness.

X. Applications

A. Freeze drying applications

Freeze drying has numerous applications beyond traditional food preservation. It is widely used in the pharmaceutical industry to preserve medications, vaccines, and biological substances. Freeze-dried foods are also popular in the camping and outdoor recreation community, as they offer lightweight, nutritious meals that can be easily rehydrated on-the-go. Furthermore, freeze drying is utilized in the production of instant coffee, powdered soups, and astronaut food.

B. Dehydrating applications

Dehydrating is a versatile preservation method that finds applications in various culinary endeavors. Dried fruits, vegetables, and herbs can be used in cooking, baking, or snack preparations. Dehydrated meats such as beef jerky are a popular choice for protein-packed snacks. Additionally, dehydrated ingredients are commonly used in trail mixes, granolas, and homemade spice blends. The compact nature of dehydrated foods makes them a convenient option for backpackers and hikers.

In conclusion, both freeze drying and dehydrating are effective methods of food preservation. Freeze drying offers superior nutritional retention, longer shelf life, and a preserved taste and texture. It is an excellent choice for those who prioritize quality and have access to freeze drying equipment. On the other hand, dehydrating offers a cost-effective and simple preservation method that is suitable for home use. It retains a reasonable amount of nutrients and is versatile in its applications. Ultimately, the choice between freeze drying and dehydrating depends on individual preferences, needs, and available resources.